ISO 13485 Year-End Requirements: Complete Compliance Checklist for 2026

Oct 15, 2025

Every December, Quality departments face the same challenge: confirming that all annual ISO 13485 requirements have been completed before the year closes. For some organizations, this is a routine verification. For others, it's a scramble to finish compliance activities that should have been completed months ago.

The difference between these two scenarios often determines how your next surveillance audit goes.

Why ISO 13485 Annual Compliance Reviews Are Critical

ISO 13485 establishes specific requirements for recurring Quality Management System activities. While the standard doesn't mandate that everything happens in December, most medical device organizations align these activities with calendar years for practical tracking purposes.

When surveillance audits occur in Q1 or Q2 of the following year, auditors will specifically look for evidence that these annual activities were completed, documented, and drove actual QMS improvements during the previous year.

Missing or incomplete annual requirements don't just create audit findings — they signal to auditors that your QMS may not be functioning as intended.

ISO 13485 Annual Requirements: 6 Critical Compliance Activities

ISO 13485 Internal Audit Requirements (Clause 8.2.4)

What's required: A complete audit of your QMS at planned intervals to verify conformity with ISO 13485 requirements and your own QMS requirements.

Common gaps we see:

Audits started but never formally closed

Corrective actions from audits still open from earlier in the year

No documented evidence that audit results were reported to management

Missing 2026 audit schedule

What audit-ready looks like: All 2025 internal audits are complete with documented findings, corrective actions tracked to closure, and a 2026 audit schedule already established showing planned coverage of all QMS processes.

ISO 13485 Management Review Requirements (Clause 5.6)

What's required: Top management must review your QMS at planned intervals to ensure continuing suitability, adequacy, and effectiveness.

Common gaps we see:

Management Review meetings happened but weren't formally documented

Required input elements missing from documentation (regulatory changes, audit results, complaint trends, resource needs)

No documented decisions or actions from the review

Executive sign-off missing or informal

What audit-ready looks like: Formal Management Review documentation showing all required inputs were analyzed, executives participated and signed off, and specific decisions or actions resulted from the review.

Document Control and Review Requirements (Clause 4.2)

What's required: Documents must be reviewed and updated as necessary at defined intervals.

Common gaps we see:

Procedures haven't been reviewed at defined intervals (many companies commit to annual reviews)

Review dates tracked informally or not at all

No documented evidence that reviews occurred or that documents were confirmed as still appropriate

What audit-ready looks like: Clear records showing which documents were reviewed this year, who reviewed them, what changes (if any) resulted, and confirmation that they remain effective and current.

Supplier Evaluation and Re-Assessment Requirements (Clause 7.4)

What's required: Critical suppliers must be re-evaluated at defined intervals and records of these evaluations maintained.

Common gaps we see:

Supplier evaluations overdue based on your own procedures

Evaluation criteria applied inconsistently

No documented plan for 2026 supplier audits or re-evaluations

Poor performance noted but no documented follow-up actions

What audit-ready looks like: All critical suppliers evaluated according to your defined intervals, documented evidence of performance assessment, and a clear plan for 2026 supplier oversight activities.

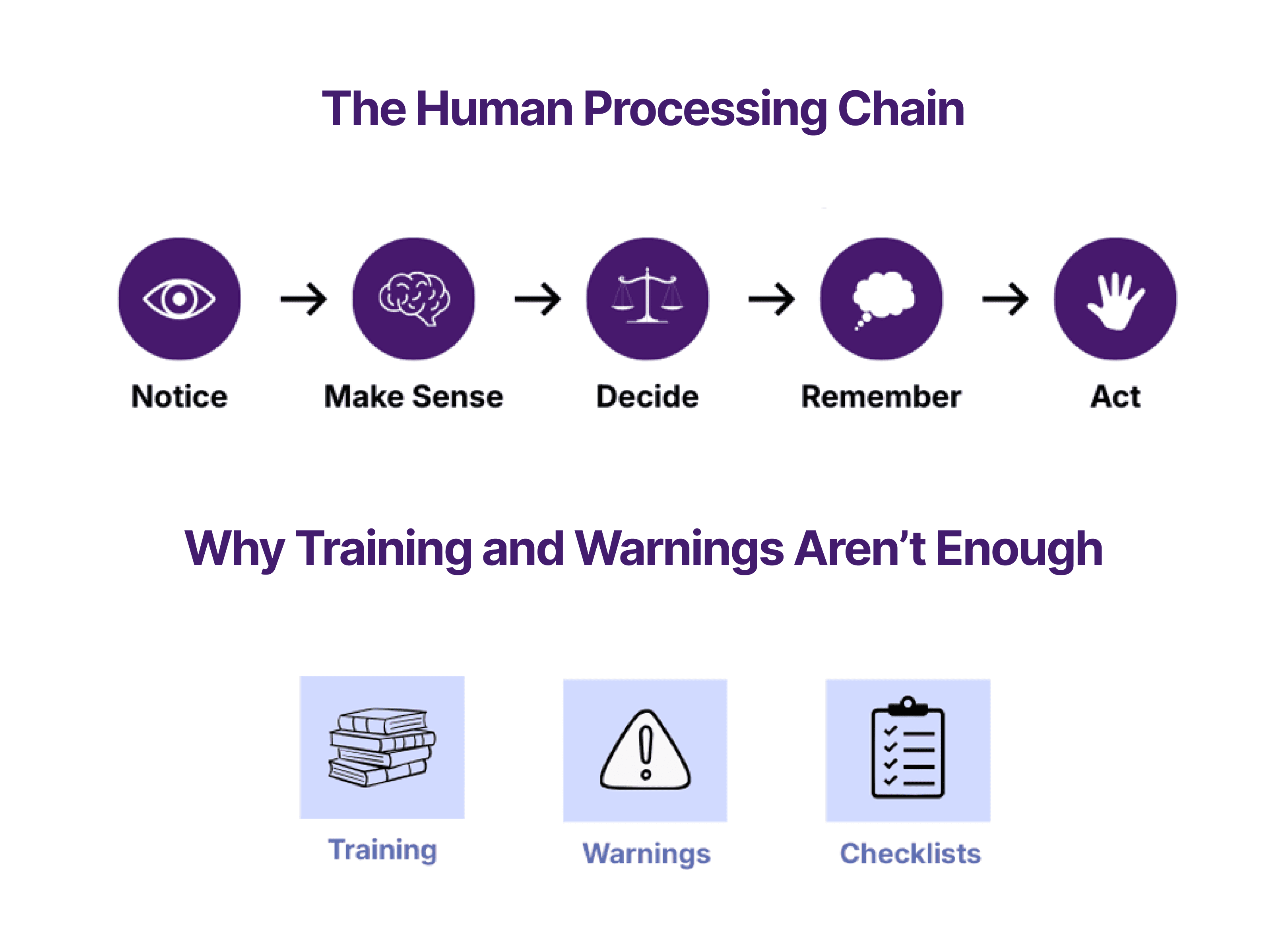

Personnel Training and Competency Requirements (Clause 6.2)

What's required: Personnel performing work affecting product quality must be competent, and training records must be maintained.

Common gaps we see:

Training records not updated after SOPs were revised

New employees missing documented training for their roles

Competency assessments not performed or documented

Training effectiveness not evaluated

What audit-ready looks like: Current training records for all personnel, documented competency assessments, and evidence that training was provided when procedures changed during 2025.

Quality Objectives and KPI Monitoring Requirements (Clause 5.4.1)

What's required: Quality objectives must be established, and progress toward these objectives must be monitored.

Common gaps we see:

Objectives set at the beginning of the year but never formally reviewed

No documented assessment of whether objectives were achieved

New objectives for 2026 not yet established

Metrics tracked but not analyzed for trends or improvement opportunities

What audit-ready looks like: Documented review of 2025 quality objectives showing what was achieved, analysis of any shortfalls, and clearly defined objectives for 2026 with associated metrics and targets.

How Leading Medical Device Companies Handle ISO 13485 Annual Requirements

Organizations that consistently perform well during surveillance audits don't treat these annual requirements as December tasks. They've built these compliance activities into their operational rhythm throughout the year.

What prepared organizations do differently:

Quarterly QMS dashboard reviews: Instead of one annual review, they conduct QMS metrics/dashboard review quarterly. This distributes the workload and ensures QMS performance is regularly assessed by leadership.

Rolling Internal Audit Schedules: Internal audits are distributed throughout the year, with different processes audited in different quarters. This prevents the end-of-year audit crunch and provides more timely feedback on process effectiveness.

Scheduled Document Reviews: Document reviews are assigned to process owners with specific deadlines spread across the year. A procedure reviewed in March doesn't need another review in December.

Continuous Supplier Monitoring: Supplier evaluations follow a calendar based on risk and criticality. High-risk suppliers might be evaluated quarterly, while lower-risk suppliers are evaluated annually — but these evaluations are staggered throughout the year.

Ongoing Training Management: Training needs are identified as procedures change or new employees join, not batched up for year-end completion.

Organizations that scramble in December typically waited too long to start these activities, underestimated the time required, or assumed they could complete everything quickly at year-end when key personnel are least available.

What Happens During Audits When ISO 13485 Requirements Are Incomplete

When surveillance audits occur and annual requirements are incomplete or poorly documented, the consequences extend beyond individual findings.

Auditors use annual requirements as indicators of QMS health. A missing Management Review signals that leadership may not be engaged with the QMS. Overdue internal audits suggest monitoring processes aren't functioning. Incomplete supplier evaluations indicate supply chain oversight may be inadequate.

These aren't just documentation gaps — they're evidence that your QMS may not be operating as an effective system.

Additionally, trying to reconstruct evidence after an auditor requests it rarely works well. Auditors can identify when documentation was created retroactively, and this damages credibility even if the underlying activities actually occurred.

How to Complete ISO 13485 Year-End Requirements in Q4

If you're facing incomplete annual requirements in December, focus on these priorities:

Assess what's actually complete. Create a clear inventory of your annual ISO 13485 obligations and their current status. Be honest about what's done versus what's partially done versus what hasn't started.

Prioritize based on audit risk. If you have a surveillance audit scheduled for early 2026, prioritize activities auditors will definitely check: Management Review, internal audits, and any supplier evaluations that are significantly overdue.

Document what you complete properly. Rushed documentation often creates more problems than it solves. If you're completing a Management Review in December, ensure all required inputs are actually analyzed and documented, not just checked off as complete.

Be realistic about what can finish before year-end. If certain activities can't be completed properly before December 31, it's better to document them as 2026 activities than to create incomplete or inaccurate 2025 records.

Plan better for 2026. Use this experience to build a more distributed approach to annual requirements throughout the coming year.

Creating a Year-Round ISO 13485 Compliance Calendar

The best time to prevent December scrambling is in January, when you're planning the year ahead.

Establish a master calendar that maps out when each annual requirement will be completed. Distribute internal audits across quarters. Schedule quarterly QMS dashboard reviews at consistent intervals. Assign document reviews to specific owners with deadlines spread throughout the year. Build supplier evaluation schedules based on risk and performance history.

Integrate these activities into regular operations rather than treating them as separate compliance tasks. QMS dashboard reviews should naturally include discussion of metrics you're already tracking. Internal audits should provide valuable process feedback, not just compliance verification. Document reviews should ensure procedures reflect actual practices.

Assign clear ownership and accountability. Someone needs to be responsible for ensuring each annual requirement is completed on schedule. This might be your Quality Manager, but specific activities can be delegated to process owners with clear expectations and deadlines.

Monitor completion status monthly. Don't wait until Q4 to check whether annual activities are on track. Monthly reviews of your master calendar ensure nothing falls through the cracks and issues are identified while there's still time to address them.

ISO 13485 Consulting: When to Get External Quality Support

Some organizations find that annual requirements consistently create challenges despite good intentions. Small Quality teams struggle to balance routine operations with compliance activities. Executive schedules make Management Reviews difficult to coordinate. Internal audit expertise may be limited. Supplier evaluation processes need refinement.

If any of these sound familiar, you're not alone.

Many successful MedTech companies leverage external Quality support to ensure ISO 13485 requirements are completed properly and on time. This support can take different forms depending on your needs: facilitating Management Reviews when executive availability is limited, conducting internal audits that provide objective assessment and valuable insights, organizing documentation to ensure audit readiness, or providing interim capacity during resource constraints.

The goal isn't just to complete annual requirements — it's to build a QMS that functions as an effective operational system rather than a compliance burden.

Preparing for ISO 13485 Surveillance Audits in 2026

ISO 13485 annual requirements exist because they work. Organizations that complete these activities properly and consistently build stronger Quality systems, perform better during audits, and create more reliable operations.

If you're closing 2025 with incomplete requirements, there's still time to finish properly. More importantly, there's an opportunity to build a better approach for 2026 — one where annual obligations are distributed throughout the year, documented correctly, and genuinely contribute to your QMS effectiveness.

Starting the new year audit-ready means your next surveillance audit becomes a routine verification rather than a high-stakes test of whether you can produce evidence under pressure.

Ready to strengthen your ISO 13485 compliance and build a more sustainable Quality approach? Explore how ClariMed's Quality Management services can help you complete year-end requirements, prepare for upcoming audits, and create systems that stay inspection-ready throughout the year — not just in December.

ClariMed helps medical device companies build and maintain compliant, efficient Quality Management Systems. Contact us to discuss how we can support your Quality objectives and ensure your organization stays audit-ready year-round.